Bright Day Graphene

Bright Day Graphene

“We are very pleased with our collaboration with RISE.”

The project with Bright Day Graphene was a step towards large scale energy storage devices based on graphene. What made the project particularly exciting was that the graphene from Bright Day is derived from biomass which significantly reduces the carbon footprint of the energy storage devices during their entire lifecycle, from production until recycling. At Printed Electronics which is a part of RISE we provided the required lab equipment as well as the experience to develop electrodes for these devices and tested the material’s suitability for energy storage applications. In addition, a major motivation for the project was the increasing interest on the market for graphene-based supercapacitors, which are one form of energy storage devices. Super capacitors with graphene-based electrodes are approaching the energy density of batteries. Super capacitors also have unique characteristics compared to batteries such as cycle stability of more than 1 million charge cycles, 90 % energy efficiency, wider operating temperature range, as well as very high charge/discharge power. This gives graphene based super capacitors a unique space in the matrix of electrochemical energy storage technologies, which market will grow as the share of renew able energy production increases.

At Printed Electronics we made stable supercapacitors from Bright Day’s graphene using suitable binders and electrolytes. In addition, based on our in-house know-how, we used additives to improve ion porosity and electronic conductivity for electrolyte systems with large ions. To test roll-to-roll production potential of the material, a printable ink was made using thickeners and plasticizers. The ink was successfully screen printed on aluminum/carbon collecting electrodes and energy storage pouch cells were made. Overall, we investigated the energy storage capability of this unique material and demonstrated the possibility of large-scale production via screen-printing. We found the results promising and are looking forward to continued collaborations with Bright Day Graphene.

We talked to Malin and Anna, the founders of Bright Day Graphene about the collaboration with RISE and PEA.

What is Bright Day Graphene and how did you come up with the idea?

Bright Day Graphene is a company that makes graphene from biomass. The idea was born out of frustration about the lack of environmentally friendly materials for energy storage on the market.

What did the process of the project look like?

At a workshop with SIO Grafen, we met Björn Norberg, who is a business developer at RISE. And the idea of a collaboration started to develop. The project was an opportunity for us to test the material we develop within the field of application for which we are developing it.

The collaboration with RISE worked very well and the people who were involved in the project were both competent and helpful. We are very pleased with our cooperation. RISE has contributed with its knowledge and resources in the field of electrode development, which enabled rapid testing of the material in this type of application on a prototype scale.

The goal for our material is for it to be used for energy storage, for example as an electrode in the way it was tested in the project. We also want to contribute to both more efficient and sustainable ways of storing energy, which also contributes to a society with more efficient and sustainable energy.

What is next?

Right now, we are working on a project to scale up our production. Parallel to that, we are looking for end users who are interested in developing products with the material together with us (and possibly RISE).

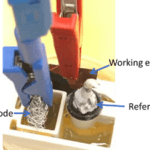

- 3-electrode investigations of the charge storage propertiesproperties

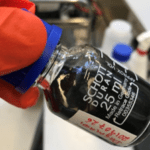

- Printable ink made at Printed Electronics from graphene-based solution

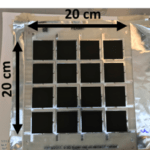

- Printing on large size electrodes

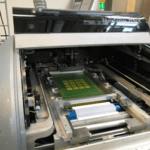

- Screen-printing machine

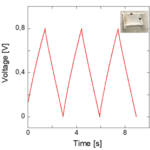

- Measurement data (pouch cell as inset)