Printed integrated circuits

Printed integrated circuits

Silicon-based electronic circuits exhibit tremendous computational power and are often used for high frequency communication. But applications requiring many contact pads, to form interfaces with sensors or displays, typically results in expensive chips due to the increased chip area. The objective of our research is therefore to combine conventional electronics with screen printed integrated circuits, to minimize the number of contact pads and, hence, the required chip area.

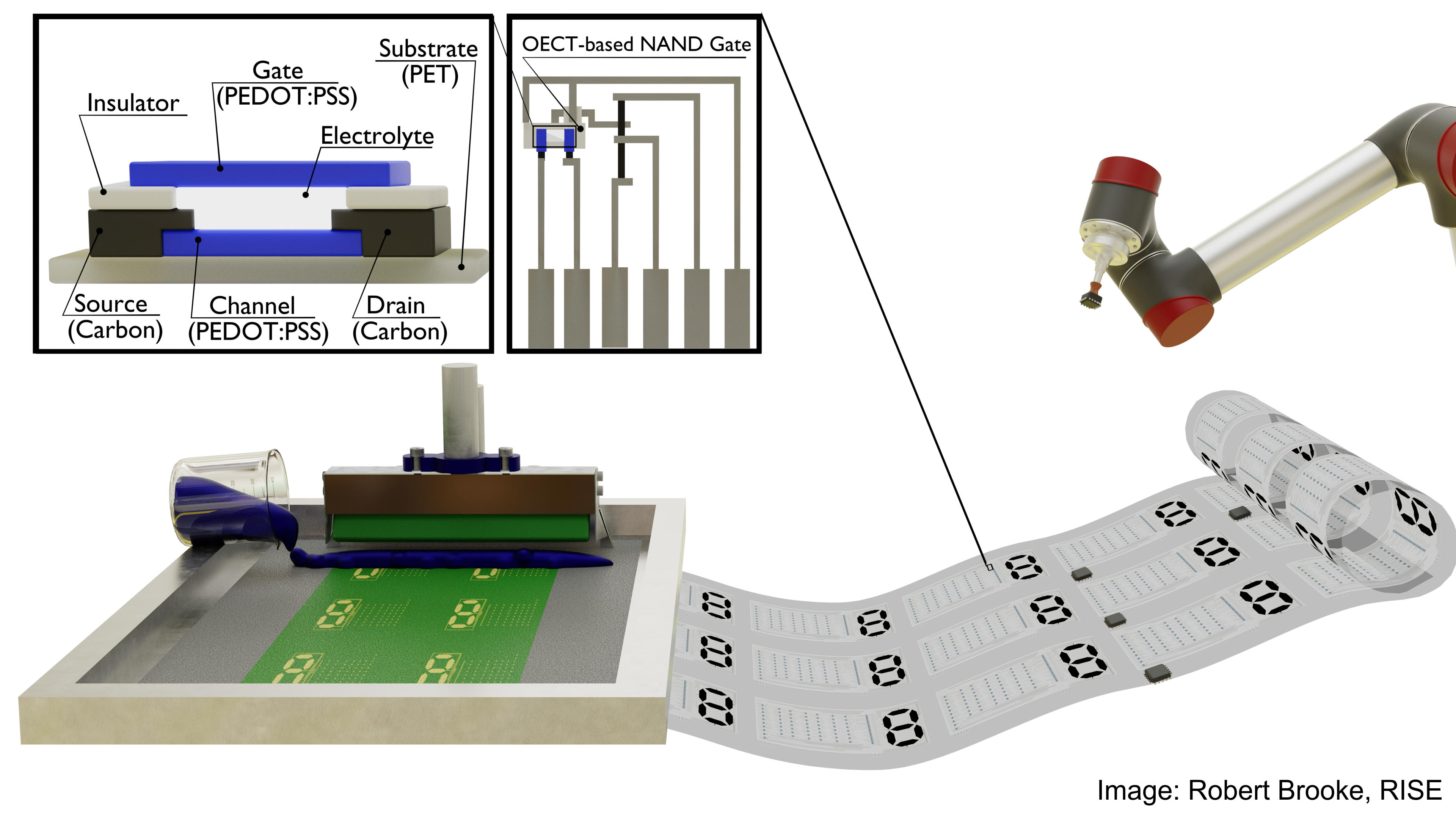

The methods to manufacture organic electrochemical transistors (OECT) have been improved during the most recent years. The uniqueness of our development is that screen printing is used for the deposition of every layer, which results in a very simple manufacturing approach. The technology provides reliable devices with high manufacturing yield, and further miniaturization have resulted in a number of different screen printed integrated circuits, e.g. 4-1 multiplexers, 4-7 decoders and 7-bit shift registers.

The main objective is to minimize the number of contact pads on the silicon chip often used for addressing of peripheral devices, such as a display. Only two input signals are required in a 7-bit shift register (data + clock signal) to enable addressing of a 7-segment display. In addition to this, monolithic integration of screen printed digital circuits and electrochromic displays has also been obtained on flexible plastic substrates. The most complex circuits contain more than 100 OECTs, these results were published in Nature Communications (open access) in November 2019.

The most recent results contain yet another successful attempt on how to obtain monolithic integration of printed OECT-based digital circuits and electrochromic displays on flexible substrates, all manufactured by screen printing. The results, which were published in March 2020 in Flexible and Printed Electronics (open access), contain evaluations of various display driver circuits and their monolithic integration with electrochromic displays. In addition to this, high current throughput is one of the unique features of the OECT technology, and this is further demonstrated in the same article by controlling the light emission in traditional light emitting diodes (LED). The printed OECTs are capable of switching the light emission on and off, despite the high currents (typically several mA) that are flowing in such LEDs. The LEDs are properly addressed by a screen printed decoder circuit, and the light emission of the addressed LED is then controlled through an additional driver OECT, also manufactured by screen printing.

Monolithically integrated OECT-based circuits and electrochromic displays, all manufactured by screen printing on flexible substrates, enable a large number of future IoT applications, for example biosensor platforms for distributed healthcare, sensor platforms for monitoring of arbitrary sensors and electronic smart labels within packaging.

Integrated circuits based on organic electrochemical transistors, OECT, manufactured by screen printing on flexible substrates.

For more information and contact visit https://www.ri.se/en/what-we-do/projects/printed-integrated-circuits